All data centers need robust cooling systems. Moreover, those cooling systems need to be both cost-effective and sustainable. Hot and cold aisle containment meets all of these criteria. Here is a quick guide to what you need to know.

Understanding data center cooling

Data center cooling is essential for both safety and operating performance. From a safety perspective, cooling helps prevent fire and helps to keep human staff from overheating.

From an operating performance standpoint, cooling is essential for maintaining optimal temperatures for equipment. It therefore protects against hardware failures and the data corruption and loss this can cause. By extension, it therefore helps to extend the lifespan of data center equipment.

Understanding data center cooling solutions

Data center cooling solutions can be grouped into two main categories. These are active and passive. Active cooling solutions require electricity to power them. They often require other resources as well such as chemicals (refrigerants) and/or water.

Passive cooling solutions do not require electricity or artificial resources such as chemicals. Most passive cooling solutions are based on the principle of airflow management. Some do use water but this water may be returned to the source and/or recycled in some other way.

Understanding hot and cold aisle containment

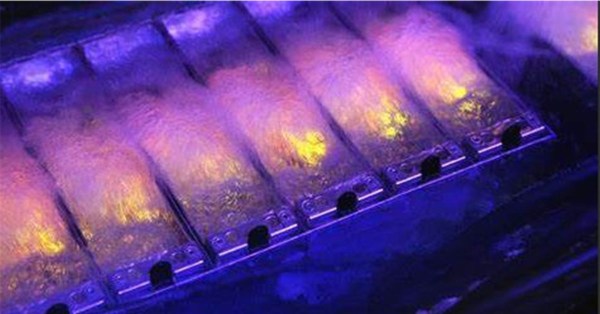

Hot and cold aisle containment is a passive cooling strategy designed to improve airflow management by separating the hot air expelled by servers from the cold air used to cool them.

In a typical setup, data center racks are arranged in alternating rows of hot and cold aisles. Hot aisles face the server exhausts while cold aisles face their air conditioners. Containment systems direct the airflow, ensuring that hot and cold air are kept separate.

Implementing hot and cold aisle containment

There are four basic steps to implementing hot and cold aisle containment. These are assessment, design and planning, installation, and maintenance.

Assessment

The assessment phase begins with a comprehensive evaluation of the existing data center layout. This includes mapping out the arrangement of server racks and cooling units, identifying the primary sources of heat, and current airflow patterns.

Tools such as thermal cameras and airflow measurement devices are used to measure temperature and airflow, providing a detailed picture of the data center’s current thermal dynamics. This data helps pinpoint areas where hot and cold airflows are mixing, leading to inefficiencies.

It’s also essential to identify the specific cooling requirements of different equipment types and their heat output. This data will be needed to develop an effective containment strategy tailored to the data center’s unique needs.

Design and planning

Design and planning involve choosing between hot aisle containment (HAC) and cold aisle containment (CAC) based on the data center’s operational needs. HAC encloses the hot aisles, preventing hot air from mixing with cold air, while CAC encloses the cold aisles, ensuring cold air is delivered directly to the equipment intake.

The server racks should be arranged in alternating hot and cold aisles to facilitate this separation. Physical barriers, such as plastic curtains, rigid metal, or glass panels, are designed to effectively separate these air streams.

During planning, a detailed budget is developed, accounting for materials, labor, and potential downtime. A project timeline with milestones ensures that each phase is completed systematically. Coordination with IT staff, facilities managers, and contractors is crucial to address potential logistical challenges and ensure seamless implementation.

Installation

Installation begins with preparing the data center for the containment structures. This includes ensuring there is sufficient clearance in aisles and verifying that there is adequate space above and around racks for installing barriers. If necessary, schedule equipment shutdowns to avoid disruptions.

Physical barriers are then installed according to the design plan. This may involve attaching plastic curtains, constructing metal or glass partitions, or assembling full aisle enclosures. All gaps between racks, floors, and barriers must be sealed to prevent air leakage. Grommets and brushes can be used for sealing cable entry points.

Cooling units and airflow management systems are reconfigured to direct cold air into the cold aisles and hot air out of the hot aisles. Perforated tiles and blanking panels are adjusted to optimize airflow, ensuring effective separation of hot and cold air streams.

Maintenance and monitoring

Regular maintenance and continuous monitoring are crucial for the long-term success of hot and cold aisle containment. Physical barriers should be inspected regularly for damage or gaps that could compromise the containment system’s integrity. Any detected issues should be promptly repaired or replaced.

Airflow management requires ongoing adjustments to maintain optimal cooling efficiency; this includes checking and cleaning filters and ducts to ensure unobstructed airflow. Temperature sensors should be installed throughout the data center to provide real-time monitoring of conditions. These sensors should be placed in both hot and cold aisles to track temperature variations accurately.

Monitoring software can analyze this data to identify trends and potential issues, enabling proactive adjustments to maintain optimal performance. Regularly reviewing the collected data ensures that the containment system continues to operate efficiently, maximizing its energy-saving benefits.